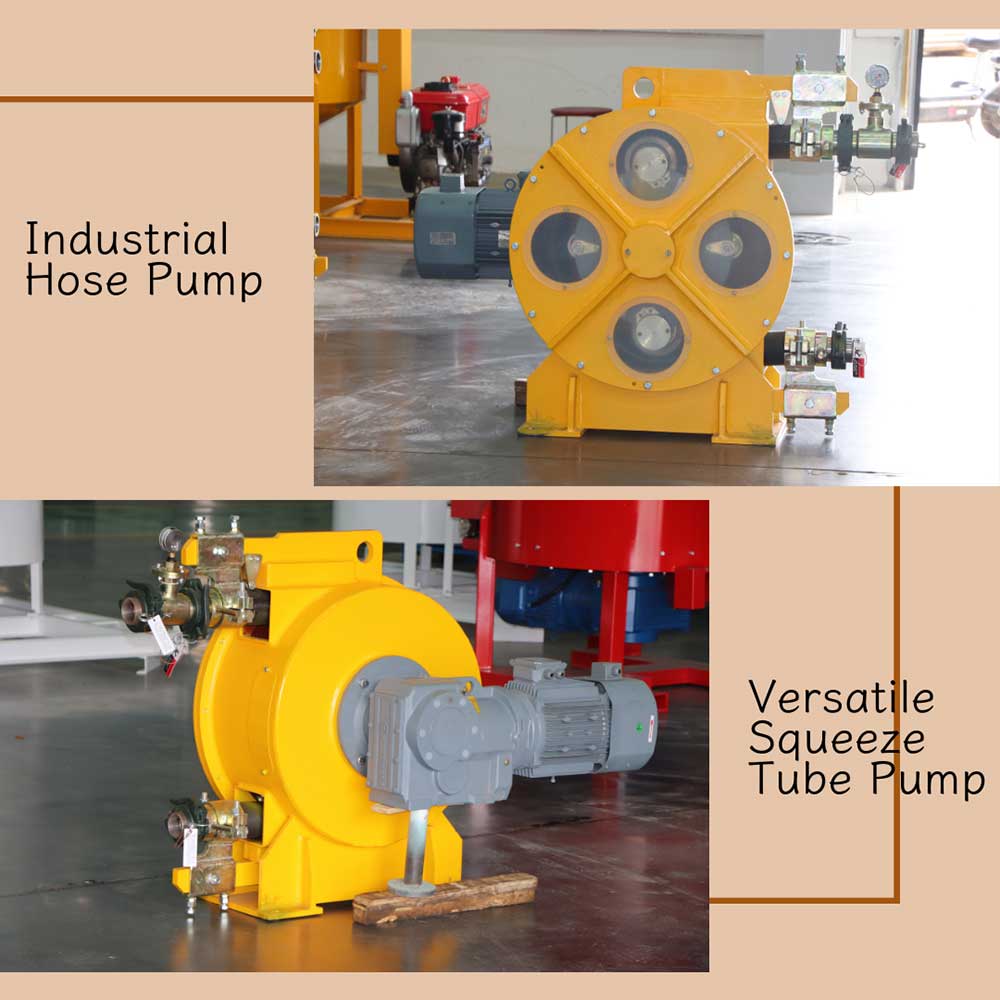

Hose Pump For Corrosive Material

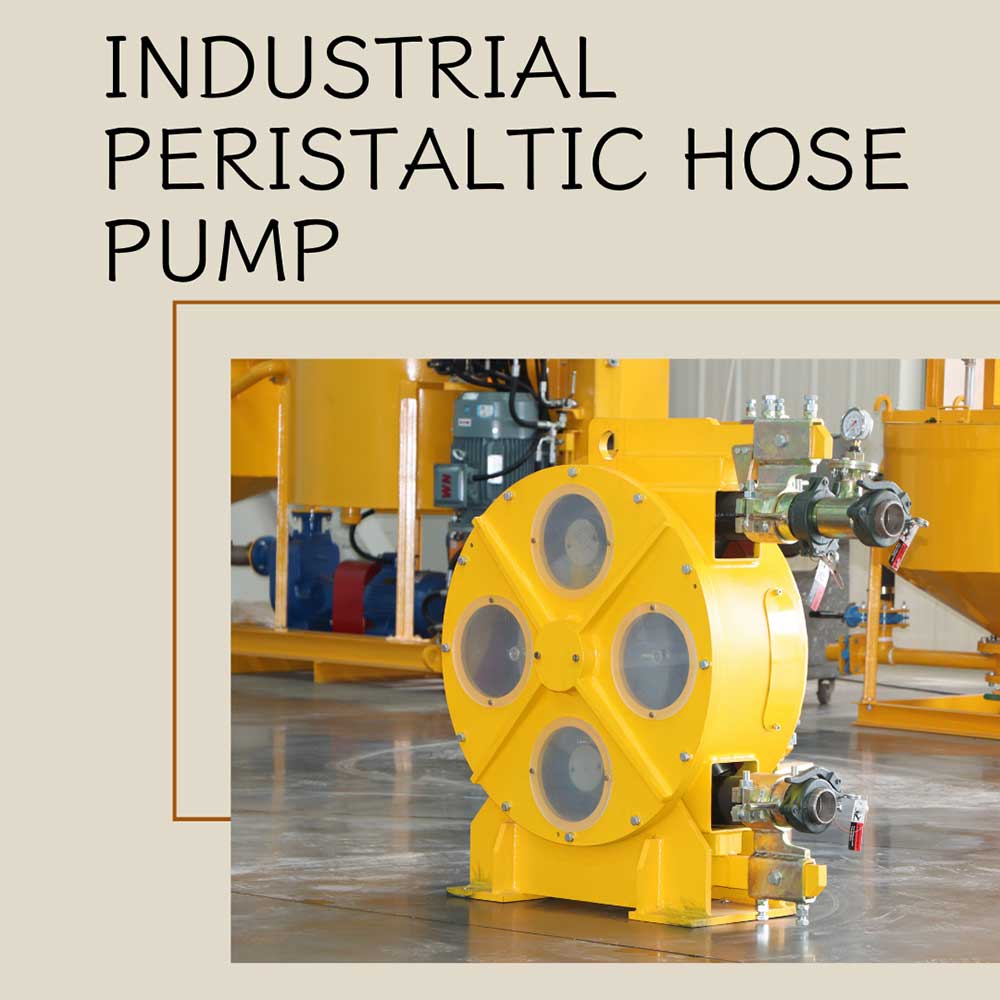

Hose pump for corrosive material operates differently. Its flow rate is independent of the medium’s characteristics and the outlet pressure remains constant per turn. This unique design allows the hose pump for corrosive material, paired with a velometer, to easily overcome the aforementioned problems. As a result, it is widely utilized in the food, healthcare, chemical industries, and laboratory measurements. Increasingly, customers are favoring the hose pump for its numerous advantages.

Hose pump for corrosive material, a high-precision metering pump, is specifically designed to measure abrasive, sticky, and corrosive liquids. Traditional metering pumps often encounter challenges when measuring viscous and abrasive media like lime or polyester. These pumps not only face issues with their own mechanics but also suffer from abrasive erosion, affecting the wetted components of the flowmeter, ultimately leading to inaccurate measurement results. Consequently, some slurries are difficult to meter accurately using traditional flowmeters.

However, hose pump for corrosive material operates differently. Its flow rate is independent of the medium’s characteristics and the outlet pressure remains constant per turn. This unique design allows the hose pump for corrosive material, paired with a velometer, to easily overcome the aforementioned problems. As a result, it is widely utilized in the food, healthcare, chemical industries, and laboratory measurements. Increasingly, customers are favoring the hose pump for its numerous advantages.

Hose pump for corrosive material boasts the following benefits:

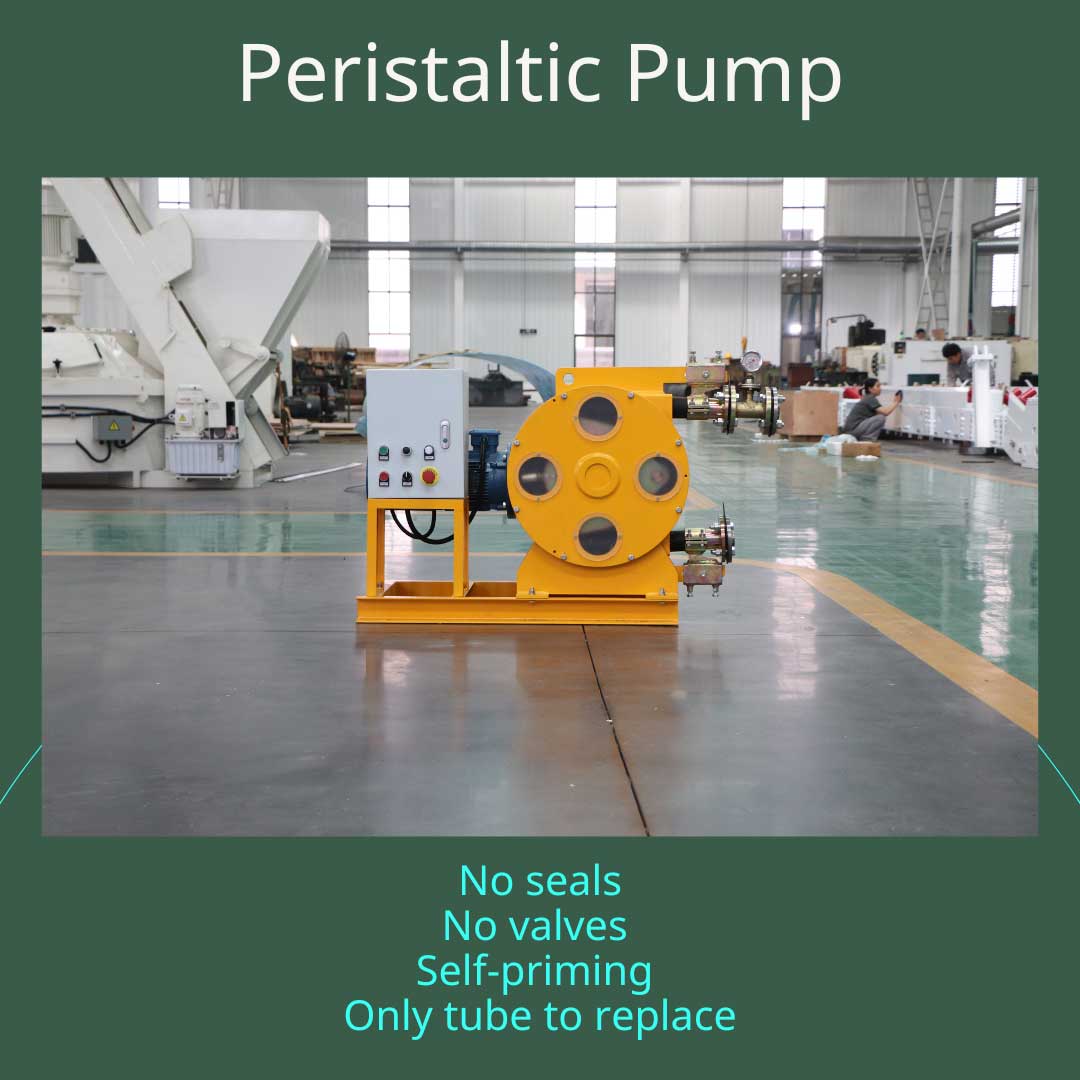

No valves required, making it ideal for pumping viscous media.

High measurement accuracy of ±1%.

Strong self-priming capacity with a vacuum degree of approximately 95%.

Continuous and uniform pumping with minimal pulsation.

Limited wearing parts; only the hose requires replacement.

Stepless flow adjustment for precise control.

Versatile material compatibility; simply replacing the hose material allows it to adapt to different applications.