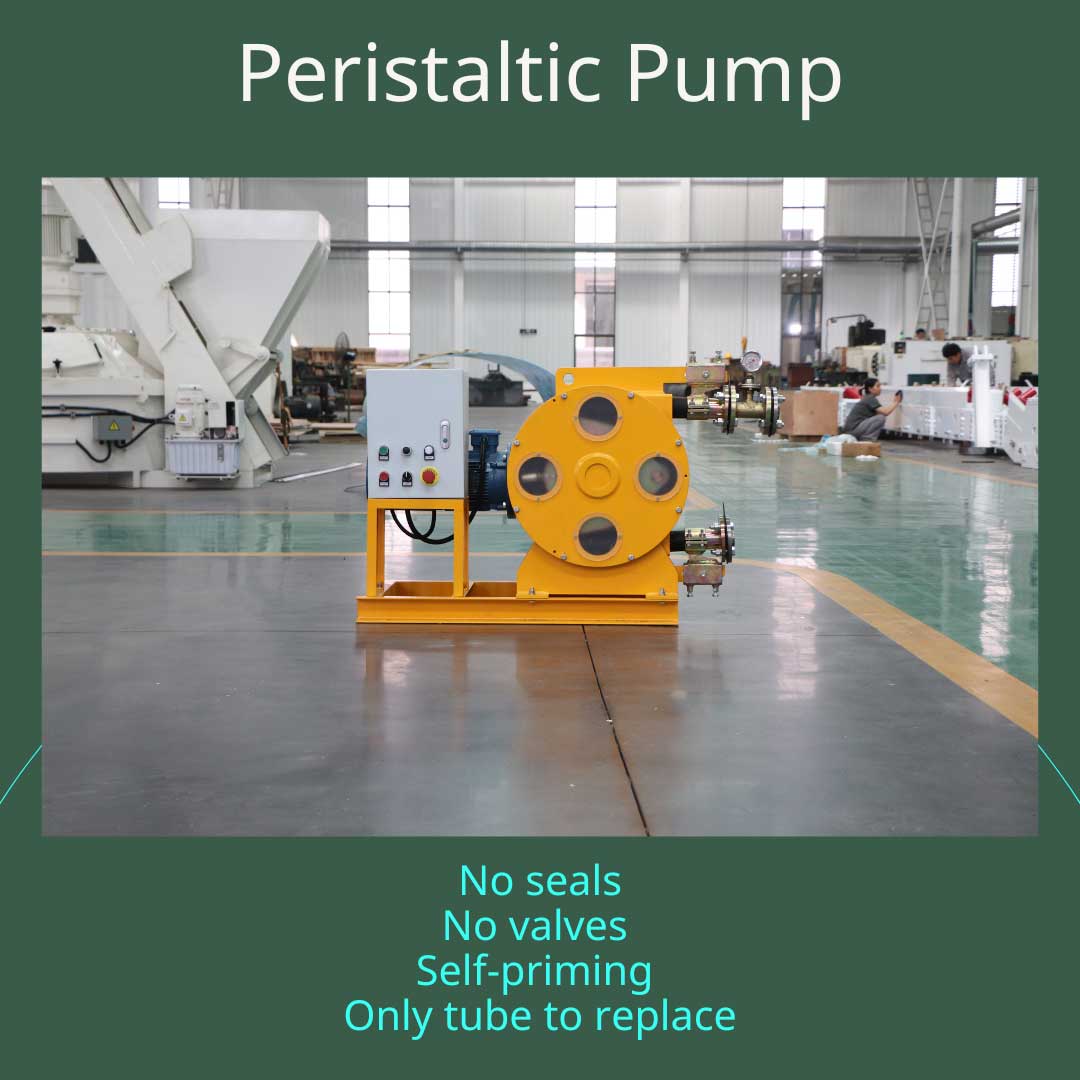

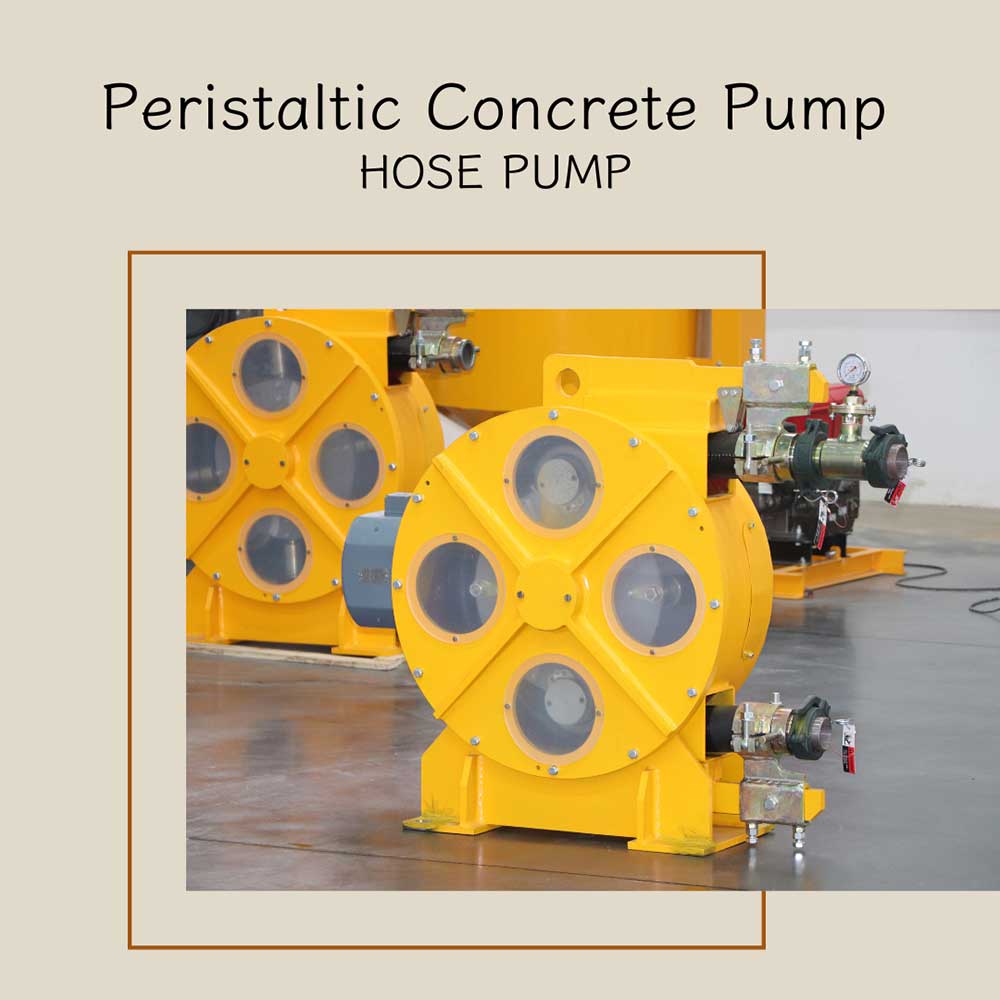

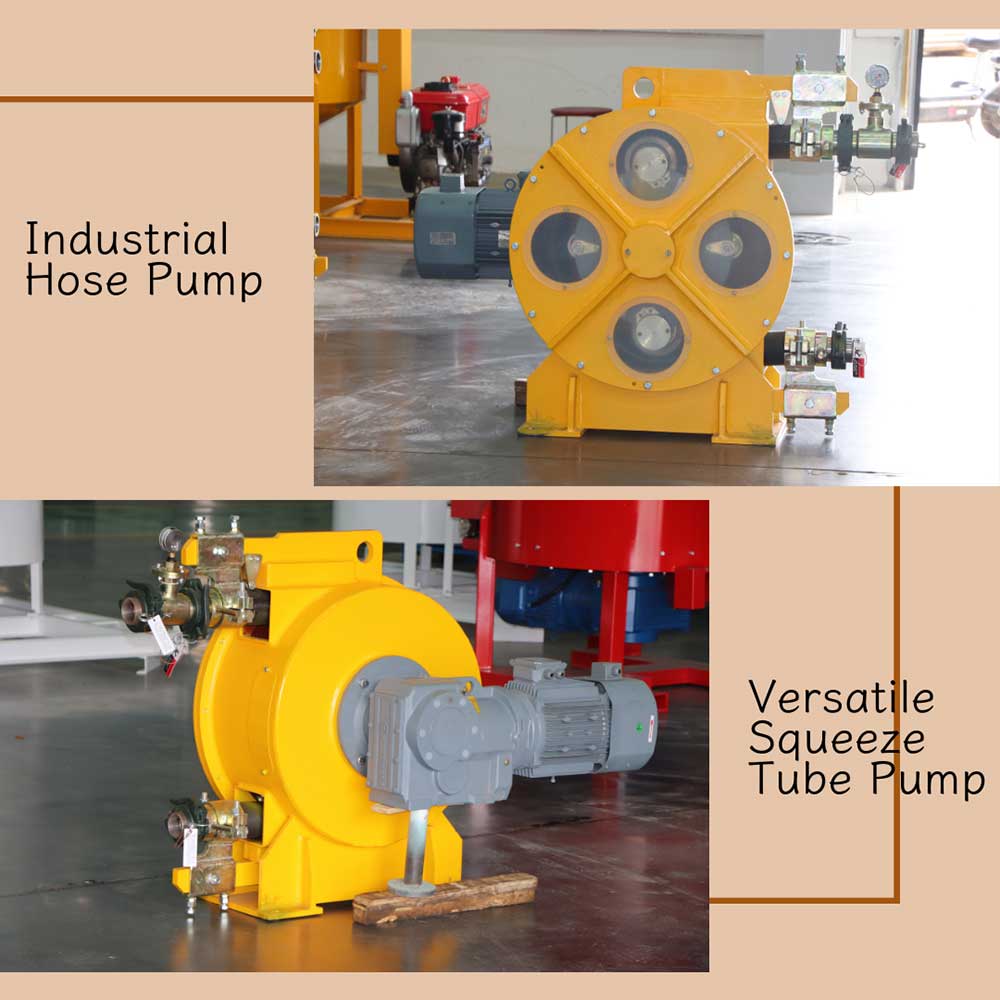

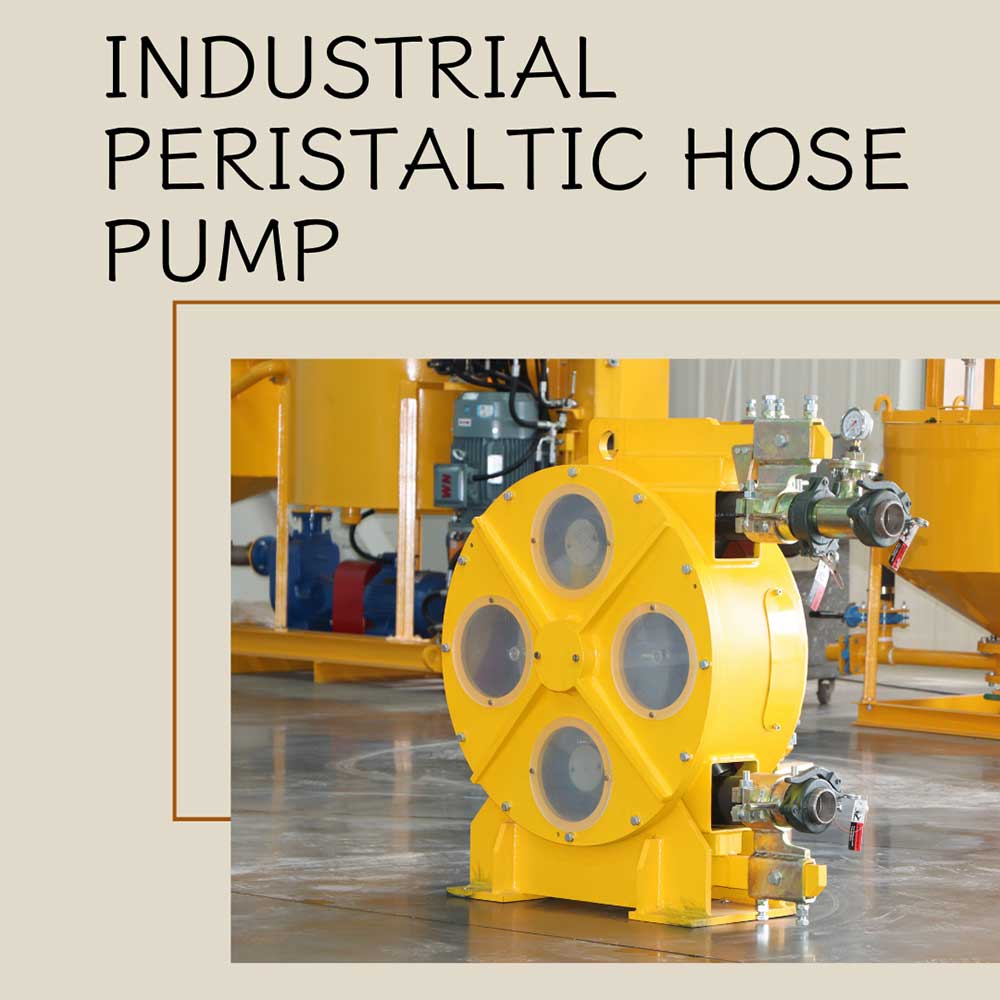

Industrial Peristaltic Pump With Customizable Flow Rates

The industrial peristaltic pump with customizable flow rates is particularly adept at handling a wide variety of fluids, including corrosive, abrasive, and shear-sensitive materials, as well as high-viscosity and high-density fluids containing large solids. With precise metering capabilities of ±1% and the ability to generate high pressures of up to 3 Mpa, these pumps are ideal for a multitude of industrial applications.

Industrial peristaltic pump with customizable flow rates is evident through their diverse applications across numerous fields. In construction, pharmacy, textile mills, dye manufacturing, water treatment, papermaking, mining, ceramics, breweries, beverage production, and underground engineering, these pumps have proven their worth.

The industrial peristaltic pump with customizable flow rates is particularly adept at handling a wide variety of fluids, including corrosive, abrasive, and shear-sensitive materials, as well as high-viscosity and high-density fluids containing large solids. With precise metering capabilities of ±1% and the ability to generate high pressures of up to 3 Mpa, these pumps are ideal for a multitude of industrial applications.

HWH series industrial peristaltic pump with customizable flow rates consists of a pump house, rotor, roller, idle roller, squeeze tube, and driving unit. When the rotor rotates within the pump house, it drives the roller to compress the U-shaped squeeze hose, causing it to deform. As the roller continues to rotate, the hose’s elasticity allows it to recover its shape, creating a negative pressure within the hose. This negative pressure acts as a suction force, drawing slurries into the pump. Under the roller’s continuous push, the slurries are discharged through the outlet, forming an efficient pressure-conveying system for viscous slurries.