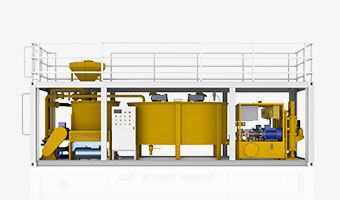

Diesel engine powered Dam grouting pump plant is widely used in dam construction and maintenance. Grouting pump plant produced by our company uses the power of diesel engine to transport stable and reliable grouting materials to ensure the structural integrity and waterproofness of the dam wall. Its high pressure capacity and ability to handle various grouting materials can ensure the accurate pouring of sealing cracks, filling gaps and strengthening the whole structure.

In addition, the use of diesel engines provides significant advantages in terms of reliability and versatility. Unlike electric-driven pumps, electric-driven pumps are easily affected by power failure or restrictions in remote areas, and diesel engines can operate independently to ensure uninterrupted grouting operations. This is especially beneficial in challenging environments, such as remote dam sites or areas with unreliable power supply.

The

HWGP400/700/80DPL-D Diesel engine powered Dam grouting pump plant is an innovative combination of a mixer, agitator, and grout pump, all integrated into a single robust base frame. Equipped with a high-speed vortex mixer, it ensures rapid and uniform mixing of water, cement, or bentonite into a homogeneous slurry. This mixed slurry is then seamlessly transferred to the agitator for further refinement. The Diesel engine powered Dam grouting pump, positioned strategically, injects the slurry from the mixing drum (storage tank), facilitating continuous mixing and grouting operations without interruption. The double-plunger pump, coupled with a sophisticated pressure-holding system, enables the pump to automatically halt and maintain minimal pressure impulses (ranging from 1-4 bar with a maximum grouting pressure of 50 bar), ensuring complete filling of the grouting holes.

The diesel engine powered Dam grouting pump plant operates on a hydraulic drive, offering adjustable grouting pressure and displacement for enhanced versatility. Its compact size and user-friendly design make it easy to operate and occupy minimal space.

Revolutionize dam construction with our powerful

diesel engine powered Dam grouting pump plant – built for reliability, efficiency, and seamless grouting operations. Request a quote today.