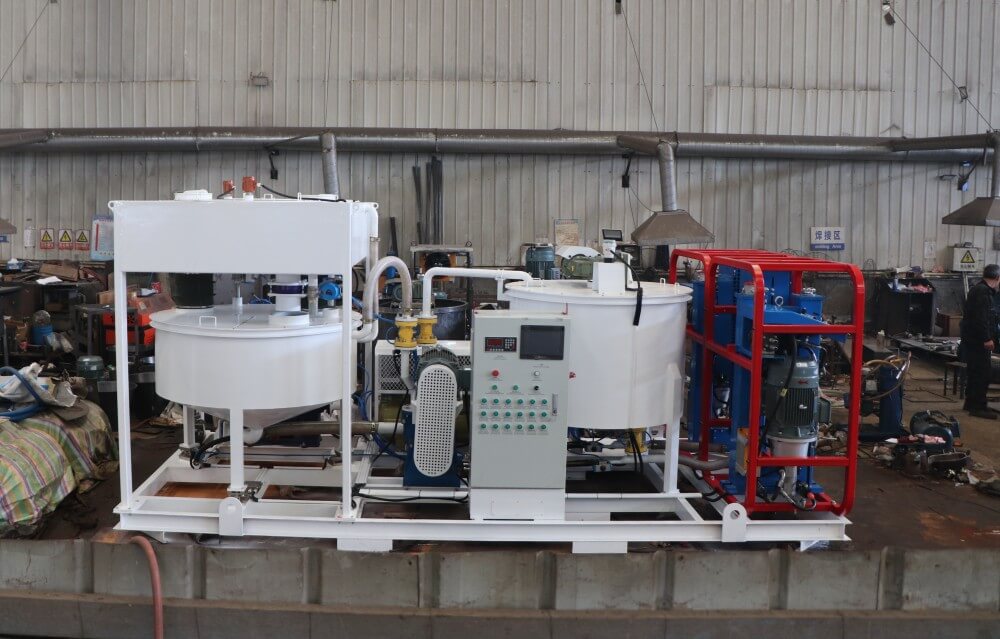

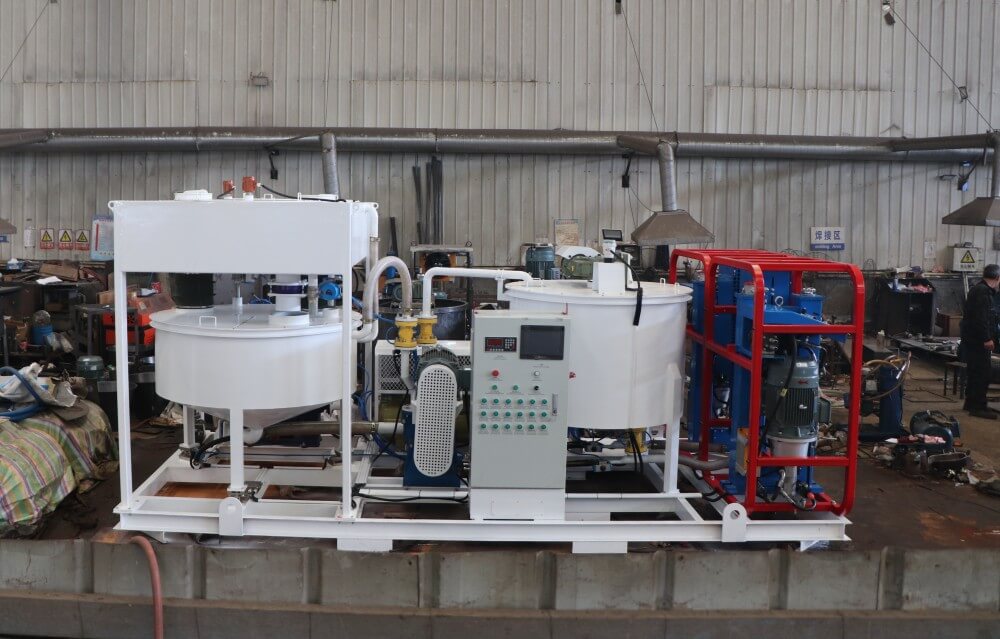

Grouting equipment for underground is an integrated device, including a mixer, a circulating pump and a grouting pump. It is mainly used to produce cement slurry and similar materials, which are used in ground and underground construction projects, including highways, railways, hydropower stations, construction projects, mining and so on.

High-speed vortex mixer helps to mix quickly and evenly, turning water and cement into consistent slurry. The mud is then transported to grouting pump to ensure uninterrupted mixing and grouting. The system is equipped with distributor and PLC, which allows flexible adjustment of the proportion of water, cement and additives. It can be configured based on automatic material formulation, thus significantly improving operational efficiency.

The following are the advantages of

grouting equipment for underground:

1. Compact design:

1. Compact design: occupies the least space.

2. Humanized operation: easy to operate and maintain.

3. Dual operation mode: automatic and manual control options are provided.

4. Cost-effective maintenance: Less spare parts are needed to reduce maintenance costs.

5. Efficient mixing: high-speed vortex mixer ensures fast and uniform mixing.

6. Customizable material ratio: allows flexible adjustment of the material ratio in the formula.

7. Automatic material management: can automatically configure and supplement materials.

8. Safety electrical cabinet: fire protection design with IP56 protection level.

9.Certification quality: in line with CE and ISO standards.

If you also need a grouting equipment for underground to help you finish your work, please feel free to

contact us.